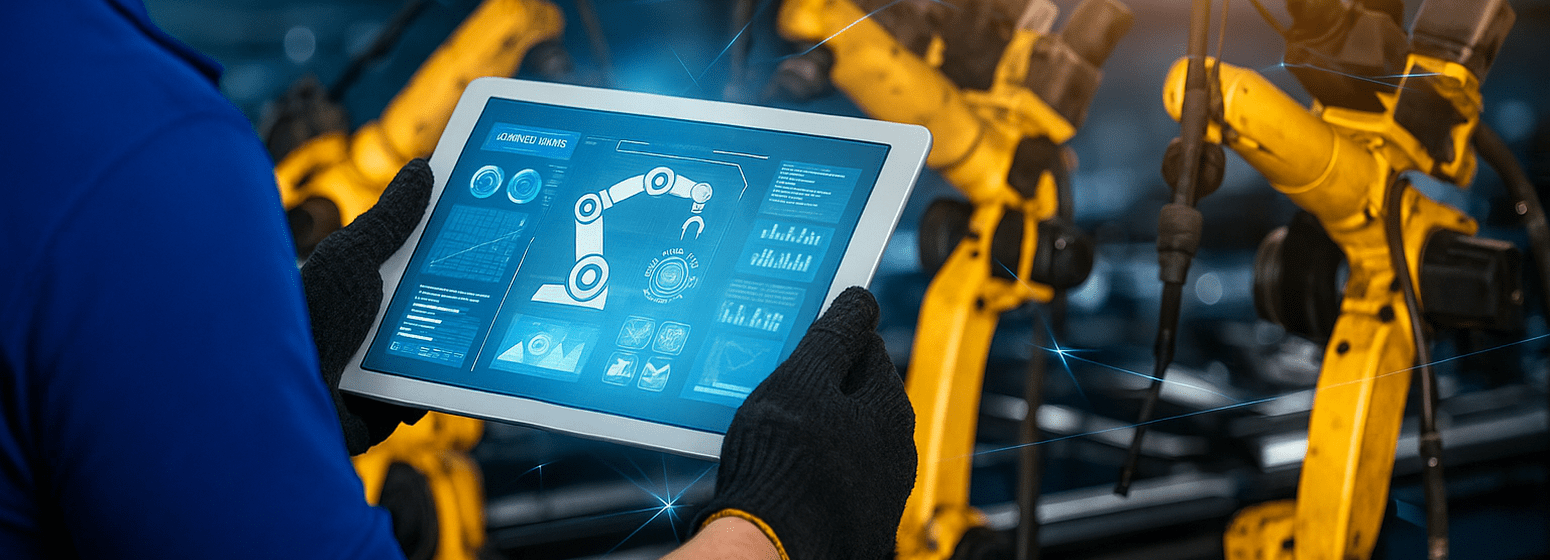

Driving Global Manufacturing And Supply Chain Operations

ExploreIntelligent Solutions

Explore DristiRFID Reader

Explore SenskonIndustrial Sensors

Unlocking excellence by driving efficiency, ensuring quality, and fostering sustainability across global manufacturing and supply chains through visibility and intelligence

Clients Served

Devices Connected

Facilities Enabled

How BCI is Powering the Future of Intelligent Supply Chains

.png&w=2048&q=75)

Comprehensive Intelligent Solutions for Enterprises

Warehouse Management System

Boost the efficiency, visibility, and control of your warehouse operations with our WMS Software

Know More

Manufacturing Execution System

Optimise your manufacturing for enhanced efficiency and superior quality control

Know More

Track and Trace

Track with confidence; scale with cloud. Achieve transparency and build consumer trust

Know More

Manufacturing Intelligence

A single-window solution built to turbocharge overall equipment effectiveness and workforc...

Know More

Supply Chain Control Tower

Harness data for real-time operational visibility and build a robust and agile supply chain

Know More

Asset Intelligence Platform

An IoT platform for better asset visibility, management, and control

Know More

Inventory Intelligence

Drive profitability and customer satisfaction with complete inventory visibility

Know MoreClients We Work With

With BCI WMS, we saw a visible reduction in operational costs. We can now completely track and trace all items in the RM warehouse, which helps us efficiently manage warehouse resources. In addition, BCI WMS’ seamless integration with our ERP gives us complete control over all transactions and inventory data in real time.

BCI WMS transformed our kitting operations, ensuring complete traceability and significant process efficiency, which resulted in substantial time, money, and resource savings. With BCI's WMS, we achieved nearly 100% inventory accuracy, successfully managing over 5,000 SKUs

BCI WMS significantly boosted efficiency and scalability for our warehouses in India. The barcode-based serialisation enables easy tracking in the supply chain, seamlessly integrating with ERPs for real-time data access. Thanks to BCI, we now have improved inventory visibility and enhanced process control with minimal intervention.

BCI’s expertise guides us through technological changes, fostering a successful partnership. This 15-year-long association has been nothing short of exceptional. We look forward to continuing this collaboration, leveraging BCI's proven track record in adapting to advancements

We highly commend BCI for their innovative solutions, which have enhanced our efficiency through advanced product traceability and automated data capture across various business divisions. The exceptional domain knowledge and timely delivery of solutions have contributed substantially to our operational effectiveness.

Shoppers Stop has maintained a longstanding partnership with BCI for over a decade. BCI consistently supports our essential mobility and printing requirements for efficient inventory data collection, providing a track record of reliable and dedicated service that has significantly contributed to the smooth operation of our business over the years.

Partnering with BCI for mobility technology needs was a privilege. Their attention to detail stands out, ensuring that our events, from conception to execution, meet and exceed high standards. Their commitment goes above and beyond, providing valuable support that significantly benefits our organisation and demonstrating high dedication.

We acknowledge the instrumental role played by BCI in addressing the challenge of tracking suppliers' vehicle movement through the implementation of their RFID-based TAT system. This innovative solution not only overcomes logistical hurdles but also enhances the overall efficiency of our supply chain operations.

BCI's deployment of an RFID-based Inventory Intelligence solution at Decathlon ensured 100% dispatch validation, enhancing visibility and stock accuracy in our warehouses. Their expertise significantly contributes to operational efficiency and reliability.

Udaan expresses gratitude for BCI's cooperation and timely problem-solving, which played a pivotal role in the success of the Udaan project. BCI's invaluable support throughout the process underscores their dedication and effectiveness in overcoming challenges, further solidifying the strength of our partnership.

Our Technologies

Automating data capture to minimise errors and enhance operational efficiency.

RFID

Dristi

Senskon

Machine Vision

Automated Labelling

Fixed Mount Barcode Readers

WLAN

Industries we serve

Our automotive supply chain management solutions drive unparalleled efficiency for OEMs and Tier 1 and Tier 2 suppliers. Driven by insights, our solutions elevate quality and efficiency to improve customer satisfaction and ensure regulatory compliance.

Electronics Manufacturing

Life Science Manufacturing

FMCG Manufacturing

Retail & E-Commerce

Transport & Logistics

Government

Our Featured Case Studies

Our Partners

Our News & Articles

26 Aug 2025

26 Aug 2025

26 Aug 2025

26 Aug 2025

Our Latest Blogs